What began as a grassroots push by a handful of determined employees in Lüdenscheid, Germany has since grown into the Mission to Zero™ model for sustainable manufacturing. To date, more than 25 facilities on four continents have achieved Mission to Zero status through a combination of smart building solutions, renewable energy, and resource-efficient tools and technologies from both ABB and third parties.

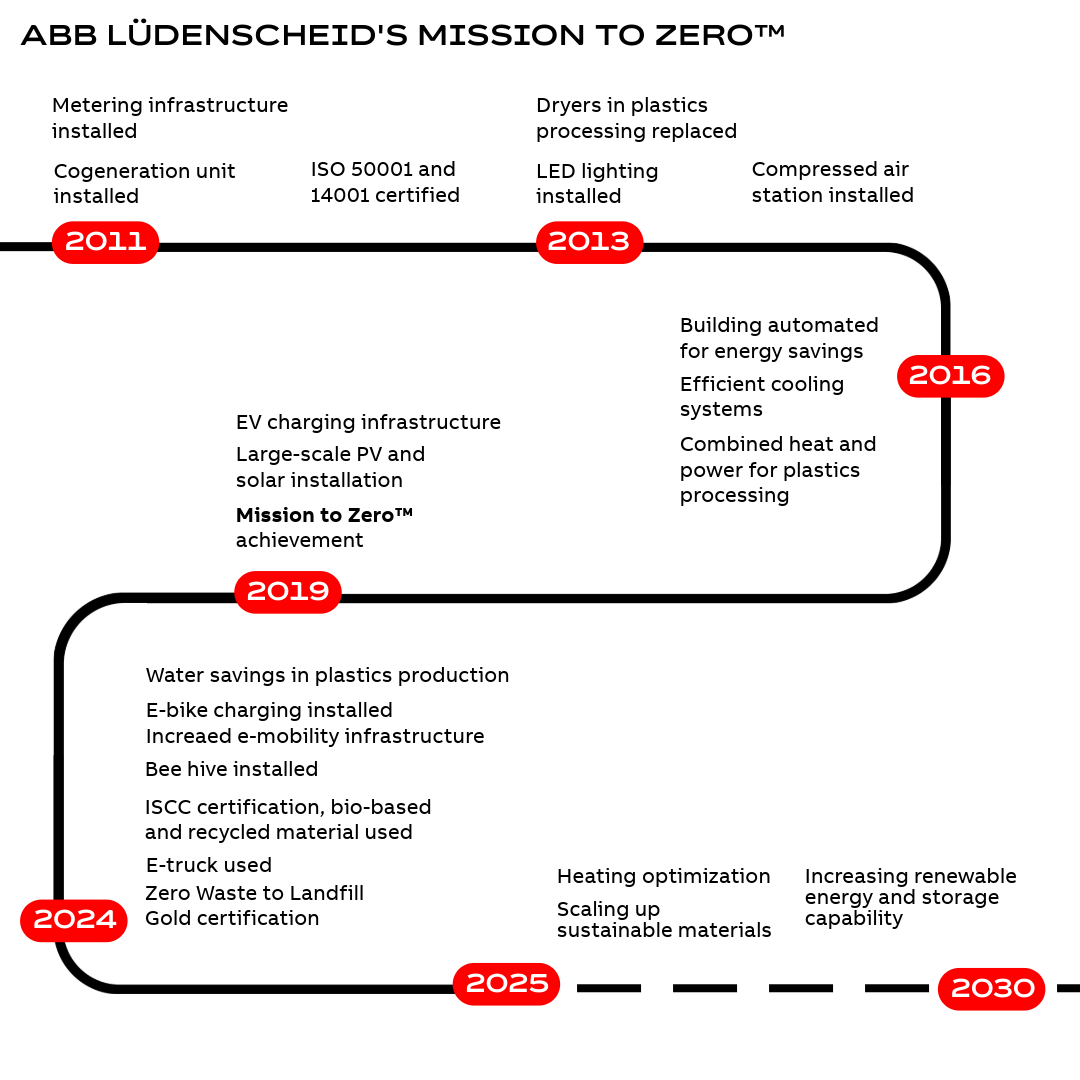

The team at Lüdenscheid had been carving an energy-efficient path well before it kickstarted the Mission to Zero movement in 2019. Energy efficiency efforts started in 2011, when the site implemented an on-site cogeneration plant, LED lighting, building automation, and other energy-efficient upgrades.

“We reached a point where that wasn’t enough,” said Lucas Bergmann, Sustainability and Infrastructure Manager. “We wanted to integrate renewable energy into our site and ultimately inspire others to follow.”

A smart, sustainable energy ecosystem

Today, Lüdenscheid produces 25% of the site’s needed electricity thanks to a 1.3 MW rooftop solar installation. An additional 25% is produced by the cogeneration unit, which captures and reuses heat generated during electricity production instead of wasting it. The ABB Ability™ Energy Manager helps intelligently oversee the full energy ecosystem, from smart switchgear to energy meters.

More than 50 EV charging stations were installed for employee and customer vehicles, and an ABB Terra 360 fast charger powers the factory’s electric truck, which shuttles materials between sites. Combined, these digitally networked solutions eliminate 750 tons of CO₂e emissions annually. *

Powered by passionate people

Lüdenscheid’s transformation wasn’t mandated from the top. The collaborative model proved instrumental in driving change by putting employees in the sustainability driver’s seat and, ultimately, creating a ripple effect across functions.

“Management empowered the Lüdenscheid team to be creative and take the lead,” said Fabio Mercurio, Emergency Lighting Business Line Leader for Smart Buildings, ABB. “Nobody had ‘sustainability’ in their title. We’re talking about production managers, people motivated by a bigger goal. Then it started to spread inside the organization.”

As Lüdenscheid’s Mission to Zero gained momentum, the workplace culture got a boost in engagement and morale. “Young people especially want to work for a company that reflects their values and is committed to building a sustainable future,” Bergmann said.

The site’s success story generated a buzz within the broader ABB community as well, igniting collaboration and friendly competition.

“It’s important for sites to learn from each other, because integrating renewables and other state-of-the-art solutions can be challenging from a technical and regulatory standpoint,” Bergmann added. “Having the head start of knowledge from a community of sites facing similar challenges is a huge benefit.”

A living showroom

Lüdenscheid showcases its solutions to guests. A state-of-the-art customer experience center demonstrates firsthand how ABB and third-party solutions can power a modern manufacturing operation.

Beyond hardware and software, an on-site beehive protects local biodiversity. Guests leave Lüdenscheid with jars of honey that serve as a sweet reminder of how small steps can make a big difference.

“We’re able to demonstrate that we are walking the talk,” Bergmann said. “We have a great story to tell – and show – that we hope inspires visitors to follow our lead.”

Sustainability from the inside out

Lüdenscheid’s commitment to sustainability extends to its product portfolio, including Busch-art linear® light switches and wiring accessories made from recycled material including old headlights and CDs. As an ISCC-recognized site, Lüdenscheid also produces products with bio-based materials, like the future® linear range of switches. In 2024, Lüdenscheid became Zero Waste to Landfill certified, receiving a Gold rating for diverting more than 95% of waste from landfills.

In the future, the team plans to renovate Lüdenscheid’s electrical infrastructure as a prerequisite for installing large-scale electric heat pumps. The renovation project will continue through 2027, with the site totally phasing out gas usage by 2030.

“Mission to Zero is not just about setting and achieving goals,” Bergmann said. “It's a starting point for a shifting mindset and a long-term commitment to innovation and sustainability. We’ve achieved great results over the last five years, and I look to the future with pride. We are certainly not at the end of our journey.”

* Compared to 2019 baseline

This is the third story in a series about progress made at our first Mission to Zero™ sites around the world. The first site featured was our Porvoo, Finland facility, and the second was our Ede site in the Netherlands. Mission to Zero is our journey to reach net-zero emissions and more sustainable operations. Bringing together technologies using ABB digital solutions and renewable energy, we’re increasing efficiency and reducing emissions at our sites. To learn more, visit our webpage.