Authors:

Alina Colling, Global Product Manager, Marine Pilot Family, ABB’s Marine & Ports division

Annaliine Tolonen, Global Product Specialist, UX design, ABB’s Marine & Ports division

Jorma Koponen, Global Dynamic Positioning Product Specialist, ABB’s Marine & Ports division

With strong encouragement from the market, ABB is proud to embark on a new chapter in vessel positioning by delivering next level DP control system performance that is fully integrated into its ship control technology.

Following significant investment and dedicated development efforts over several years, and close collaboration with our pilot project partners, we now introduce the ABB DP control system for DP2 applications. Based on a truly pioneering vision, ABB’s new solution for DP pushes the boundaries of what is possible in ship control.

We saw an opportunity to make DP better

Thousands of vessels have been built featuring DP capability over the last 50 years. Increasing numbers, and the growing variety of vessel shapes and types using DP has brought accumulated industry knowledge, experience, and the training standards that should ensure competence.

However, with increasing DP Vessel activities, so has the number of DP incidents.

To understand the root causes of DP events we studied the DP event reports published by the International Marine Contractors Association (IMCA) and the Marine Technology Society (MTS) DP committee’s “Learning from incidents” reports. We established the following:

- The root cause of several collisions was the result of confusion over which thruster control system was in command when changing from Autopilot (AP) manual levers to DP control, and between Auto DP and Independent Joystick (IJS), etc. This is described, for instance, in [1].

- As highlighted by [2] (Unintentional selection of manual mode) in an incident report that is reinforced by Australian National Offshore Petroleum Safety Authority (NOPSEMA) [3], double push, hard buttons do not provide an adequate barrier against human error. This design flaw has led to numerous instances of functions being inadvertently disabled, resulting in DP drift-offs.

- As shown in the example incident report [4] How is your alignment?, the Position reference system (PRS) locking onto an incorrect target causes an unintentional vessel movement. Once more, in [5] "Position reference problems again! The dangers of recalibrating", the PRS recalibrated without proper validation, resulting in a 40 m drift. These examples identify the risks of automatic enabling of PRS without the operator having the opportunity to quality check the reacquired signal.

We took these lessons as inputs for our control system development and complemented the findings by consulting a group of experienced DP Captains and DPOs on a regular basis. This group of Subject Matter Experts are still part of the ongoing development and improvement process at the ABB Marine Pilot Control (MPC) DP department.

Building the basis for the new DP control system

ABB has delivered both classed and unclassed DP systems on a wide range of vessels, spanning a wide range of applications—from the Ritz-Carlton exploration yacht [6] and the Keppel Offshore and Marine autonomous tug [7] to P&O Ferries’ fast ferries P&O Pioneer and P&O Liberté [8], Lisbon’s high-speed ferries [9], the Canadian icebreaker [10], and the latest ICON [11] and Oasis series of cruise ships. Each project deepened our understanding of the real-world challenges of DP and the technical possibilities, while also validating our broader vision on ship control, technology choices and the User Experience (UX) approach. These insights shaped a new design philosophy: DP systems should actively support the operator, not just control the vessel. That thinking has led us to the next big step—our novel DP Class 2 system for DEME’s (previously Havfram Wind) WTIVs [13].

The new ABB DP control system is inbedded in our ABB AX Bridge [13] and grounded in the principles of Marine Pilot Control (MPC), in order to directly address key operational challenges such as continuous control, clarity of command transfer, and deliberate Position Reference System (PRS) management. By leveraging dynamic thruster and vessel models, we can enable more predictable, efficient, and safer operations—opening the door to new levels of performance across the board.

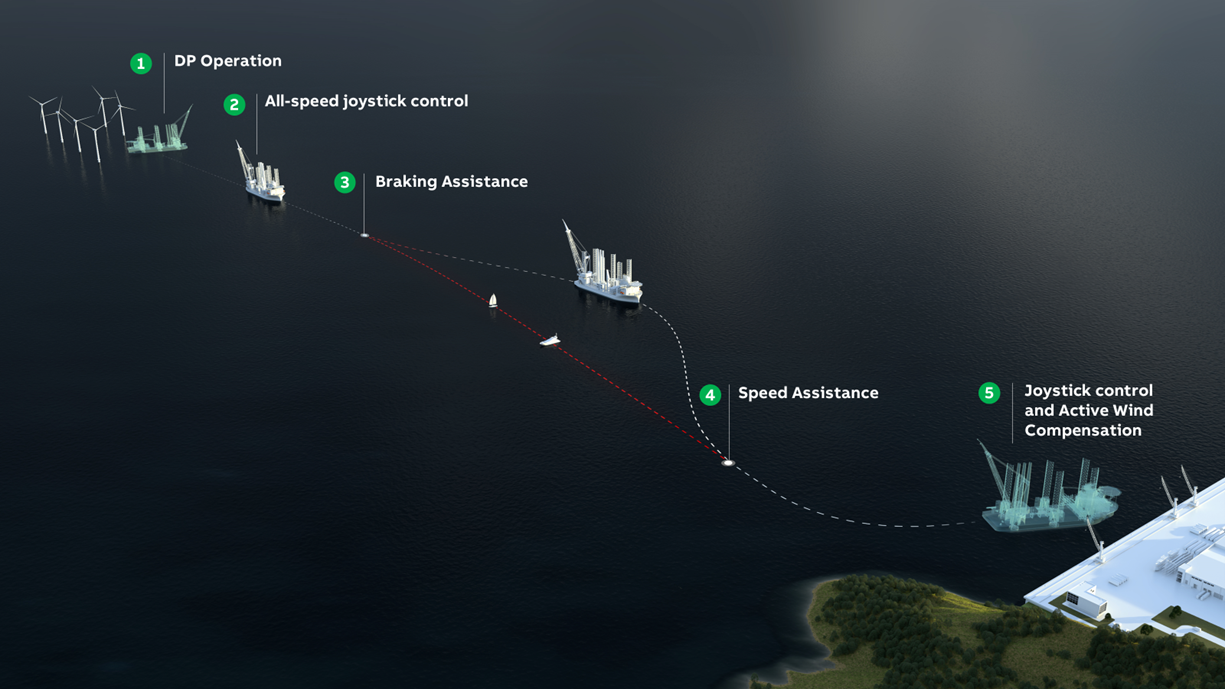

Continuous control—no more standby gap. While sailing in transit, whether using manual levers or joystick, the ABB DP control system is constantly enabled, with its models continuously updated based on sensors, GNSS PRS and thruster feedback signals. The moment the operator switches to DP mode, the DP controllers are immediately ready for any operator action. This means that the traditional DP ‘standby’ mode during which the model is built before engaging DP is simply removed. As Captain Harry Verhoeven said: “This eliminates the no-man’s land of standby mode… and increases operational safety and speed not having to wait 15 minutes for the model to build.”

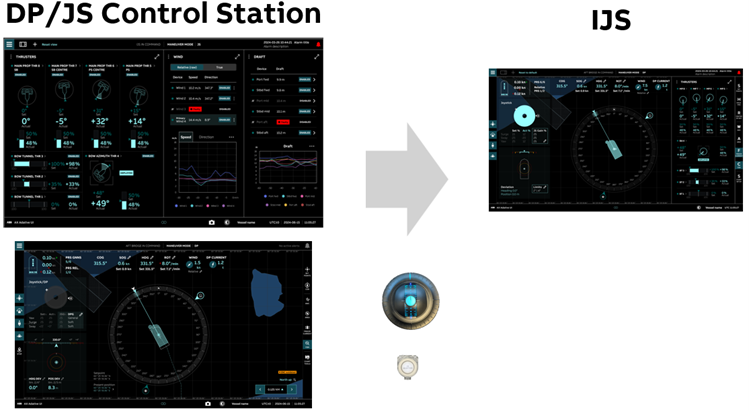

Clarity at command transfer. With ABB’s continuous control, the operator always knows whether it is the thruster control system, the DP control system, the IJS, or the local control system that is in command. This is achieved through clear status indicators on all AX UI screens, LED indicators [13] on the levers, and audible changeover signals. The integrated design prevents accidental switchovers and removes ambiguity about which system has authority – eliminating the guesswork that has historically led to drive-offs during mode changes.

Deliberate PRS management. Instead of silently reintroducing failed sensors, ABB’s system requires a two-step confirmation before re-enabling any PRS. Operators must first understand the reason a sensor was rejected to prevent position jumps or other undesired behaviors. The user interface makes it clear whether the failure was due to the sensor itself or a failed data quality test, ensuring the DPO makes an informed decision and preventing the DP controller from taking silent actions that could compromise safety.

Simplicity in the use of emergency systems. ABB unifies DP, the joystick, and the independent joystick (IJS) under a single interaction logic, with visualization showing which system has control. Shared functionalities – such as alarm handling, alert limits, gain settings, sensor and thruster enabling, station keeping and position setpoint change functions – are identical from an interaction perspective. This means there is no learning curve when switching to the IJS or bridge backup systems, which significantly reduces stress in emergency situations.

Marine Pilot Control’s DP always follows the Azipod® propulsion operational guidance. Our systems are designed for operational excellence, and to perform even better together than they would do on their own. Aligning with all operational guidelines and modes with Marine Pilot Control functionality ensures optimal thruster efficiency and reduces wear and tear and prevents misuse by design. Azipod® propulsion [14] operational guidelines require RPM in restricted zones are reduced to prevent washing the other thrusters: this is also a clear design choice in our DP system that cannot be overridden.

DP control with User Experience at its heart

IMCA data shows human factors dominate DP incidents—but the real culprit is control system design that overloads humans. ABB treats user experience as a safety system. We have invested in UX based on expertise built during over a decade of product development. From the beginning, our vision for safer, simpler, and standardized maritime user interfaces has aligned perfectly with open-source design systems like OpenBridge and Google Material Design. By combining UX expertise and knowledge embedded in our development process with the OpenBridge design principles, we have gone beyond the available standards by creating UX focused on clarity and consistency. These principles have been extended through co-creation with industry experts and end users, validated through user testing, and specifically tailored for Dynamic Positioning (DP) applications.

The result is a DP Control system that supports DPOs to always have full situational overview and to make safer operational decisions.

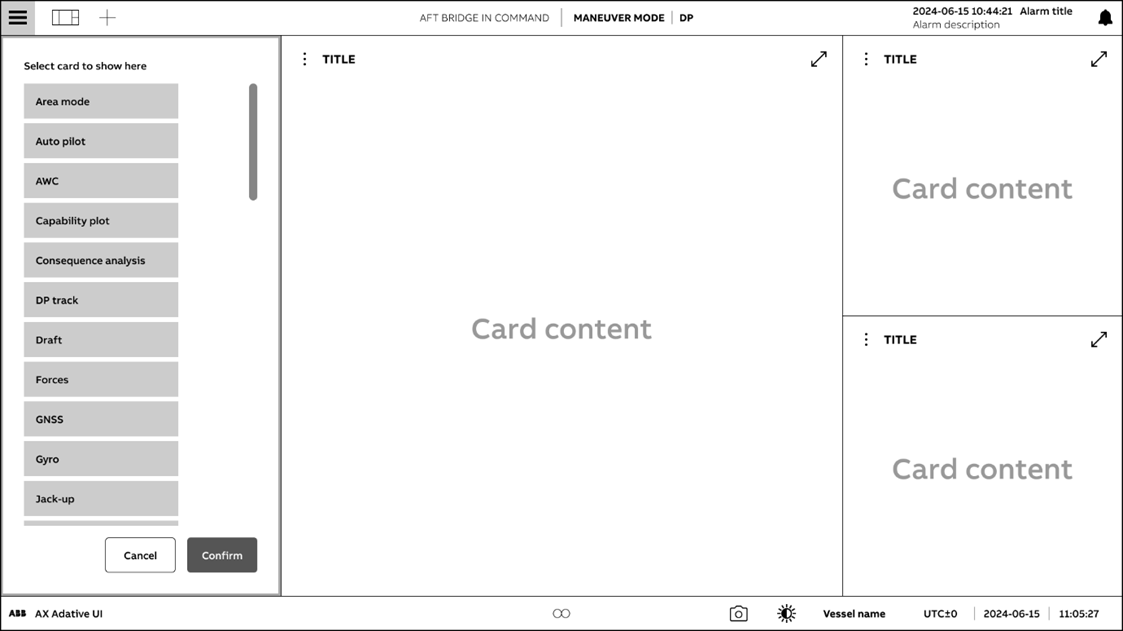

Touch panel PC with modern look and feel. ABB’s DP control station features a modern touch panel designed with safety and usability at its core. Its interface combines a clean look that ensures transparency and intuitive navigation. Embedding user logic inspired by the screens people interact with daily, every element nurtures familiarization. This creates a workplace that feels as advanced as the technology it controls.

Reducing cognitive load and clutter. The new design allows the system to display information only when it is needed, while giving operators more room to work. The four displays ensure that critical station keeping data remains visible. It also enhances situational awareness by integrating data from other systems, such as power and energy management, to support troubleshooting. The way information is presented prevents clutter by using content cards that come in S, M, L, and XL sizes. This lets the operator choose the right level of detail. Layouts are fully adaptable to task and personal preference, yet remain clean and consistent, supporting faster comprehension and safer, more efficient operations.

The information design puts the operator at the center, delivering a DP control station that combines clarity and flexibility to enhance safety, reduce cognitive load, and create the bridge environment of the future.

References:

[1] DPE 02/23: Human factors – Training for new vessel essential)

[2] DPE 01/18: Unintentional selection of manual mode)

[5] DPE 04/23: Position reference problems again! The dangers of recalibrating

[8] ABB powers P&O super-ferries towards new sustainable transport era | News center

[9] ABB sets course for sustainable river transport with ten all-electric Lisbon ferries | News center

[10] ABB Joins Seaspan Shipyards on New Canadian Coast Guard Polar Icebreaker

[13] ABB’s new DP2 functionality delivers major improvement in vessel control during DEME sea trials