Summary

The challenge

MVZ Medizinische Labore Dessau Kassel GmbH, was looking to automate most of its pre- and postanalytical phases in the laboratory processes at their hospital laboratories to improve and standardize the total workflow. These labs operate in three shifts which often involve routine manual work, exacerbating the shortage of skilled lab technicians. The organization was also seeking to speed up its processes to increase sample throughput and deliver results to the clinicians more quickly.

The solution

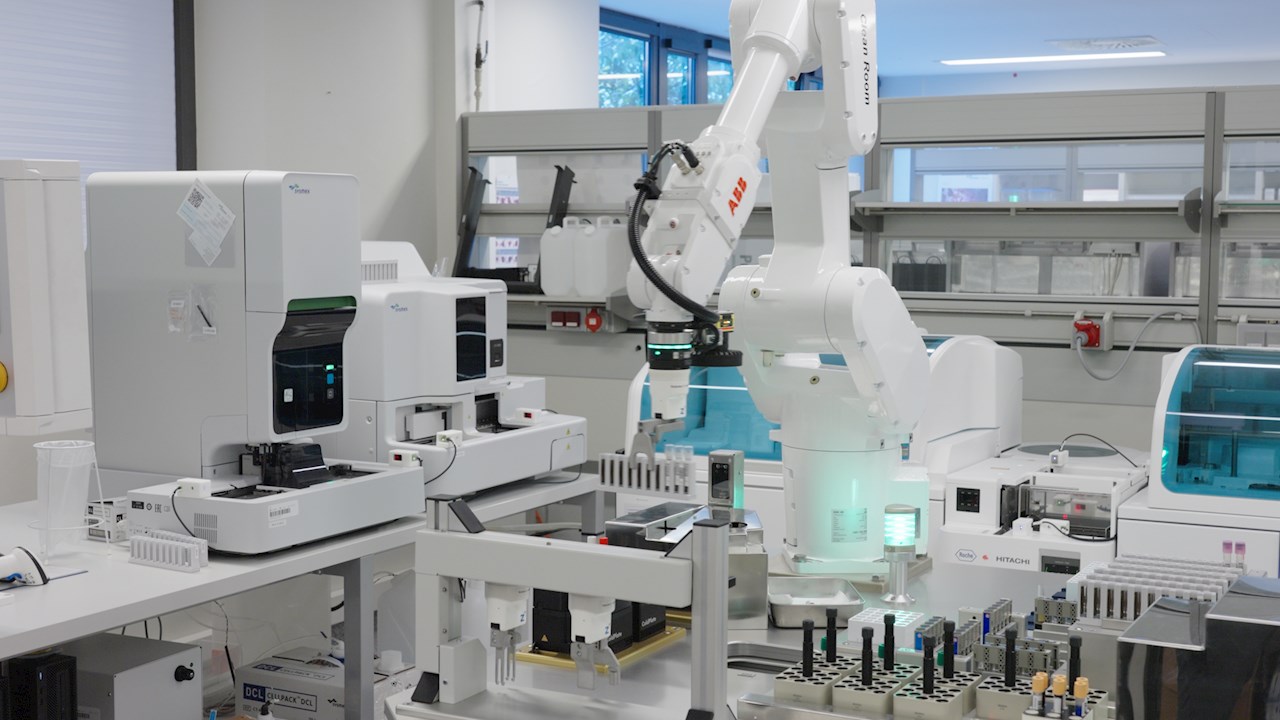

Operating on an automated laboratory table, two cleanroom-qualified ABB IRB 1300 robots collaborate safely and seamlessly with laboratory technicians, relieving them of the tedious task of handling blood samples while increasing throughput and improving ergonomics.

The application

In a medical laboratory run by MVZ Medizinische Labore Dessau Kassel GmbH and installed in a general hospital in Halle, Germany, an automated laboratory table equipped with two ABB Clean Room robots accelerates pre- and post-analysis of blood samples in close collaboration with lab employees in 24/7 operation.

MVZ Medizinische Labore Dessau Kassel GmbH, part of the Limbach Group, Germany’s largest owner-managed laboratory group, runs laboratories specialized in all kinds of laboratory medicine services. It serves hospitals, clinics, outpatient clinics and medical practitioners in multiple locations across Germany.

Every year, over 300 MVZ employees process more than 1.8 million orders and carry out about 8.5 million laboratory tests. Offering over five thousand services, including toxicological and microbiological analysis, the company has vast experience in automating laboratory diagnostics, particularly in clinical chemistry, hematology, coagulation and molecular biology.

While large medical laboratories commonly use automated and connected instrumentation (total lab automation, or TLA) for analysis and sample handling, MVZ sought to address the scarcity of flexible automation for labs in smaller hospitals with up to 600 beds.

MVZ reached out to ABB to develop a cost-effective and compact solution for automated blood sample handling in clinical laboratories. The aim was to create a self-sufficient, easy-to-operate setup that maximizes throughput 24/7, 365 days a year.

Named the Lab Table II, the automated solution developed by ABB in collaboration with MVZ can handle up to 160 samples per hour, covering all aspects of the process, from sample reception to analysis to archiving.

How Lab Table II works

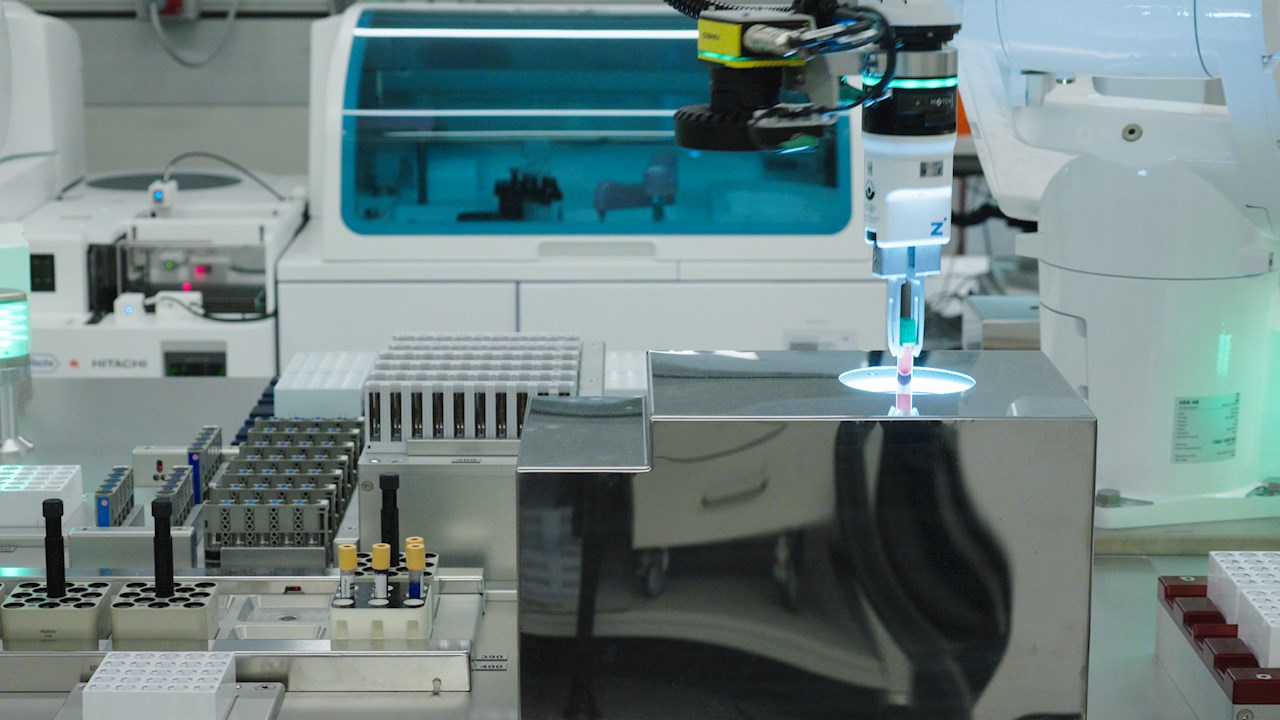

At the heart of the automated workbench for pre-and post-analysis are two ABB IRB 1300 industrial robots in cleanroom version. The robots perform a host of tasks from the moment blood samples are received until they are archived for future reference.

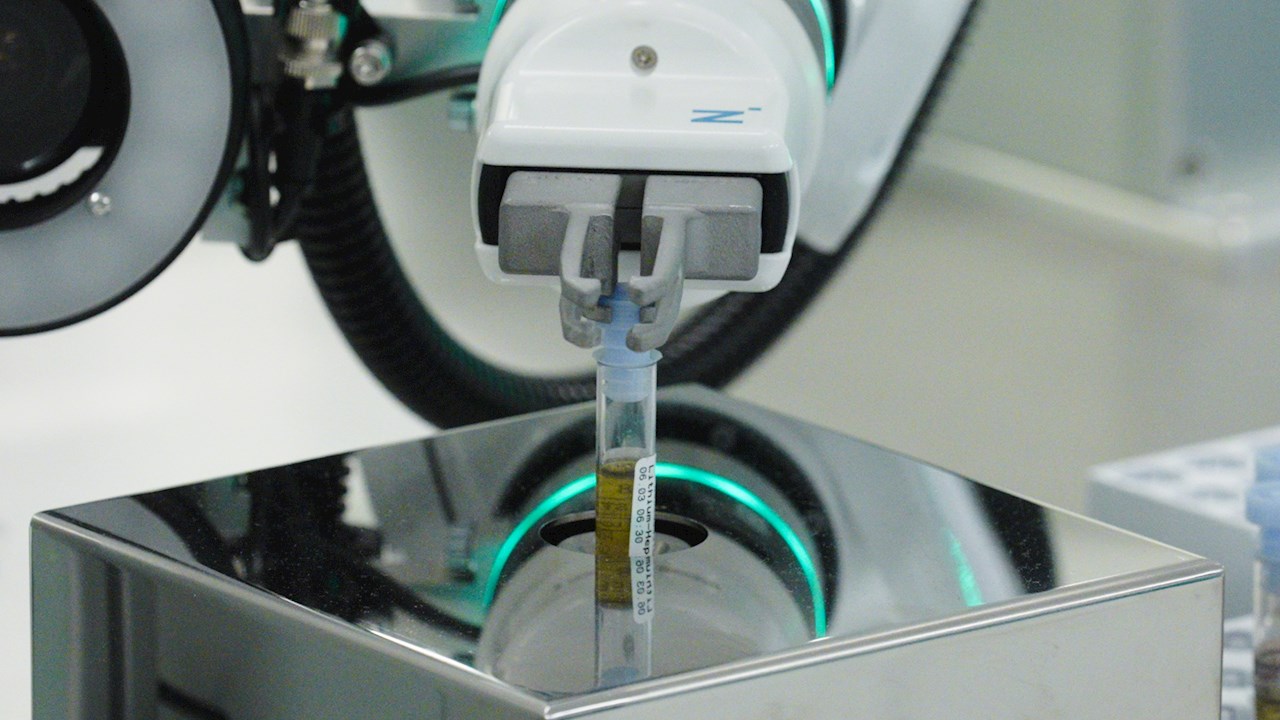

Lab staff place blood samples on the robot workbench in defined sample racks. From here, the robot takes over the subsequent activities. Upon identifying the right blood sample to test from the rack of patient samples, one ABB robot places it in the centrifuge cup, or directly in instrument racks if centrifugation is not required.

To balance the centrifuge, a second ABB robot inserts compensation tubes. The centrifuge beakers are then placed in an under-table centrifuge, closed, and the samples are centrifuged.

Afterwards, blood samples are placed in sample racks again. The second robot feeds both centrifuged and non-centrifuged samples into specific instrument racks for analysis. Once analyzed, a sensor alerts the robot to transfer racks to the output area. The robot removes, reseals, and then archives the samples.

To positively identify samples, a camera reads the color of the sample cap which identifies the kind of sample (serum, anti-coagulated blood etc.) and scans the ID-number on the tube. If there are any discrepancies, the robot sorts out the sample and places it on an error rack. Patient samples without an ID-number also wait in a special error sample area before a new scan attempt is made. If the ID-number can be read successfully, the corresponding requested analysis is downloaded to the instruments from the internal laboratory information system and the samples are processed by the robot table according to the workflow.

Robots boost productivity, safety and much more

Unlike conventional manual sample handling, where lab staff spend their precious time performing everyday repetitive tasks, the robotized solution works without interruption, achieving a throughput of 160 samples per hour. MVZ calculated processing time to be 25 percent faster, thanks to the automation solution.

MVZ was particularly impressed by the speed, repeatability, accuracy and the 1.40-meter reach of the ABB robots. Another key factor is the seamless human-robot collaboration via SafeMove, ABB's safety-certified software. SafeMove works with sensors that track all movements in a pre-defined area around the automation solution.

If a person enters the safety area, the industrial robots slow down their movement to a safe speed. When the person moves away, the robots accelerate. This makes it possible for lab staff to approach the analyzers without having to worry about colliding with the robots.

"Achieving such a high throughput in a collaborative scenario is no trivial undertaking and was only possible with our sophisticated concept," said Max Novotny, Sales & Business Development Manager, ABB Robotics. "With the help of SafeMove, however, it was possible to use an industrial robot in a collaborative scenario without a physical housing. And thanks to the active support of the MVZ team, we were able to get this exciting project over the finishing line in just one year."

The robot-based Lab Table II not only promises a significant increase in productivity, but also a considerable improvement in working conditions in the medical laboratory. Thanks to automation, laboratory staff no longer have to spend so much time on routine sample handling but can devote themselves to more demanding activities - for which there is now significantly more time thanks to the high level of efficiency.

"The ABB experts have managed to transfer their experience and know-how from industrial automation to the requirements of a medical laboratory in an extremely effective way - an impressive achievement," says Dr. Juliane Böttcher-Lorenz, Managing Director and Medical Director, MVZ. " The finished laboratory table fully covers the complex processes of pre- and post-analysis, so that small and medium-sized hospital laboratories are ideally equipped for future challenges such as the shortage of skilled staff."